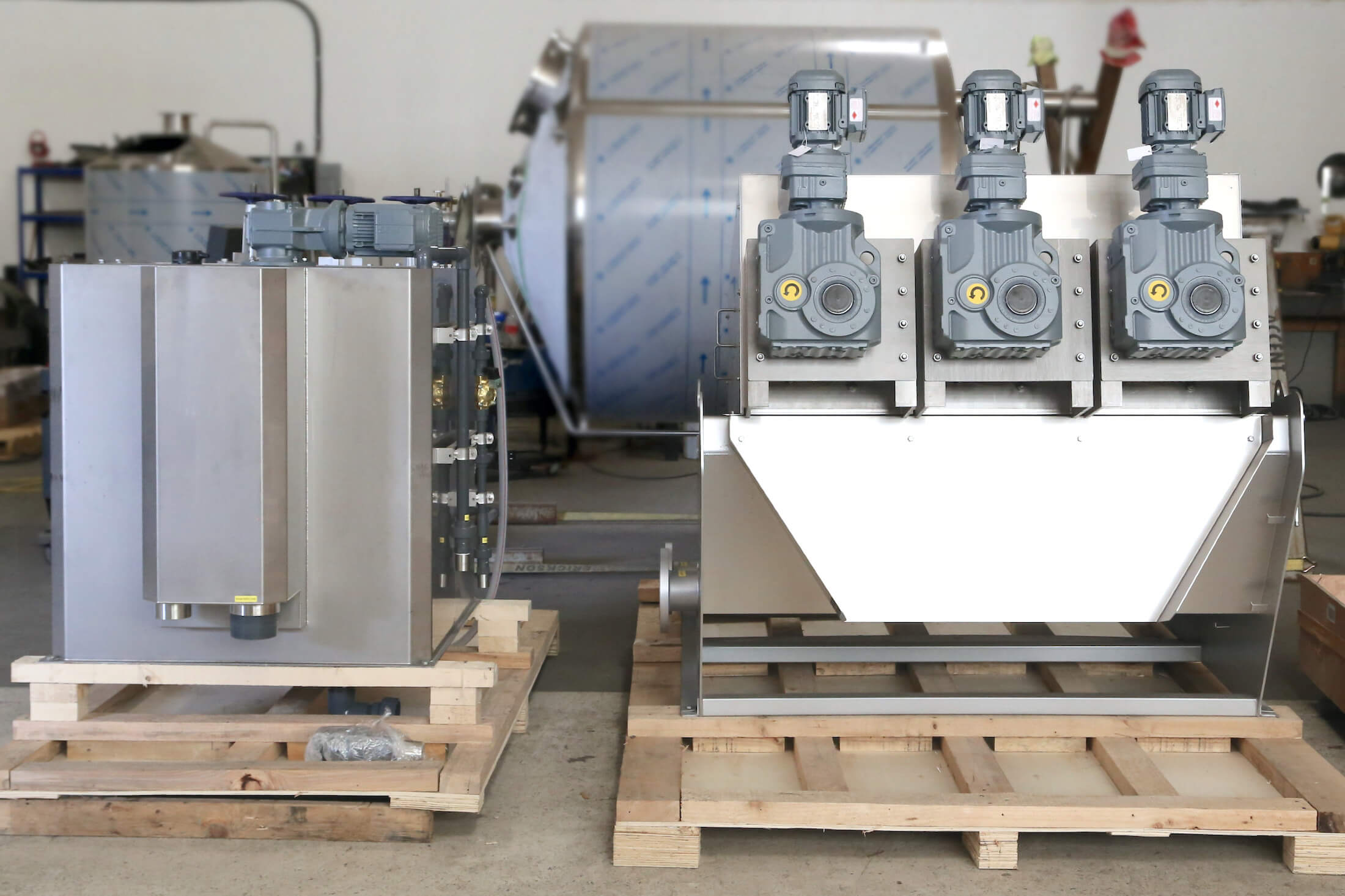

Sludge dewatering at Santa Fe WWTP

When the Santa Fe, New Mexico wastewater treatment plant started to plan an upgrade to their sludge dewatering process, Trident’s team consequently consulted with the client and helped assess suitable treatment options. The client emphasized the importance of separation performance…