Trident’s 1xx and 2xx MD presses offer compact design and remarkable performance. Effective sludge treatment…

Solid-liquid separators for food processing waste

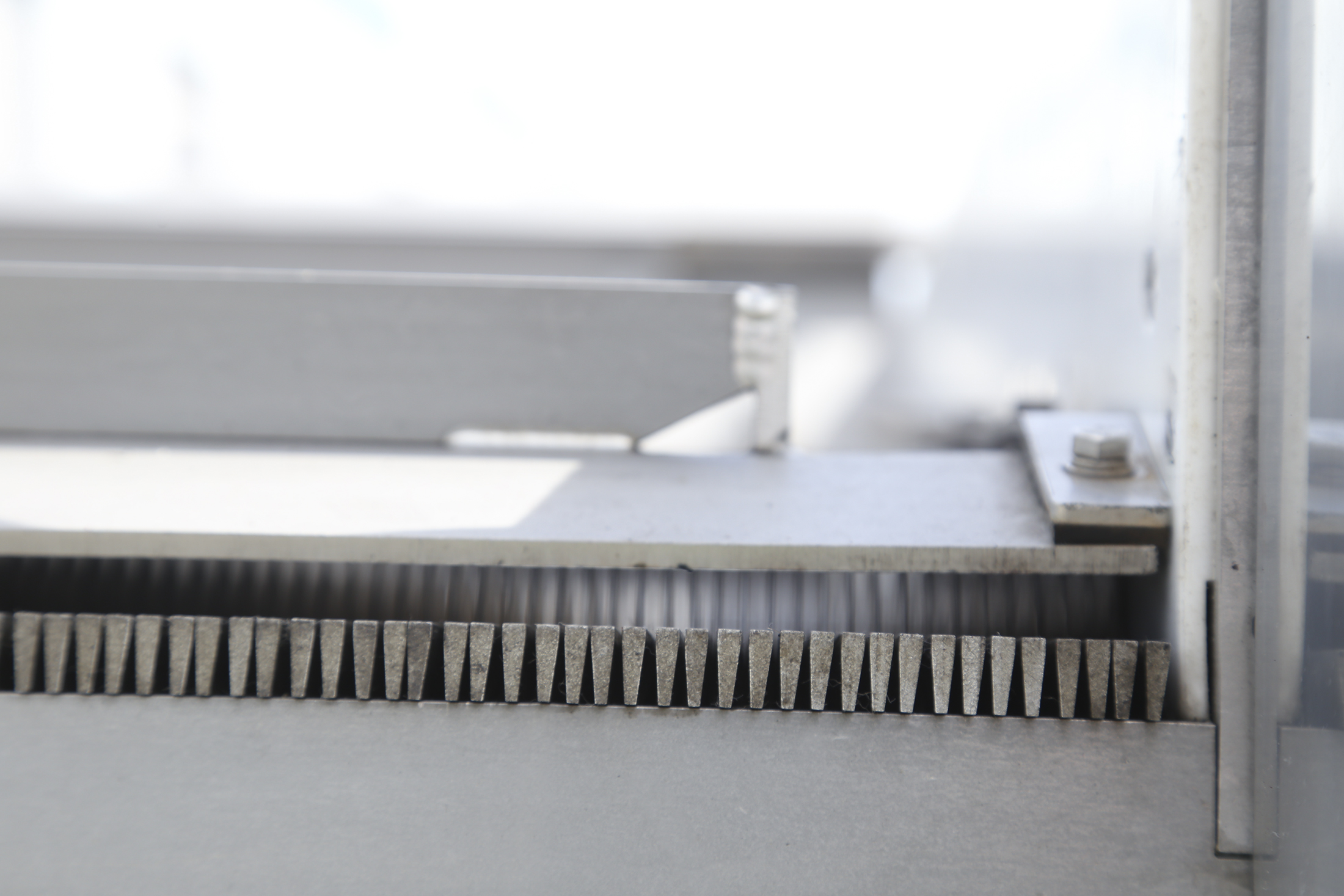

One of the main objectives when processing liquid waste from food processing applications is the separation of organic materials from the liquid. Effective separation can benefit product recovery and allow the upcycling of valuable components. Or it can help reduce hauling and disposal cost, which is often a significant expense for businesses. Which separation treatment to choose depends on the waste characteristics, particle size, expected capture rate and more. Mechanical separation like screening is suitable as a first step in the removal of suspended solids. Choosing an appropriate screen opening size will have a direct impact on the solids removal. As for the screen type, common options are perforated screens or wedge wire screens.

Image: Internally fed drum screen separator is often used for primary manure treatment

If the goal is to process slurry or sludge material coming from a screening or thickening process, which has already removed a majority of the larger organic solids, a polymer assisted treatment may be the recommend next step. Flocculants and coagulants help initiate the separation of fine solids. A subsequent low impact separation treatment, for instance with the Wave Separator, will then remove the flocculated solids and produce very clean effluent.

Trident’s range of solid-liquid separators offers a solution for every application. A rotary drum screen is suitable for the primary screening or pre-thickening. A mechanical screw press is ideal for dewatering, especially for organics based wastes commonly produced in the agri-foods sector. The capable MD Press and Wave Separator are then very efficient options for the secondary treatment which involves the use of polymer. As a tertiary treatment option Trident utilizes different filtration options that are capable of removing the remaining particulate from water.

What all Trident separators have in common is the fact that they are quality built and designed with efficiency in mind. They don’t require extensive operator oversight, use motors with low horsepower requirements and the treatment process is suitable for a wide range of applications while maintaining excellent separation performance. In addition to its standalone separation equipment, Trident also has the capability of designing systems that fully integrate in clients’ existing processes. That may include process controls or ancillary components like custom stands, bulk conveyors or pumps.

To learn how a Trident separator can benefit your application, give our team a call at 1.800.799.3740.