When the Santa Fe, New Mexico wastewater treatment plant started to plan an upgrade to…

Small sludge press offers big benefits

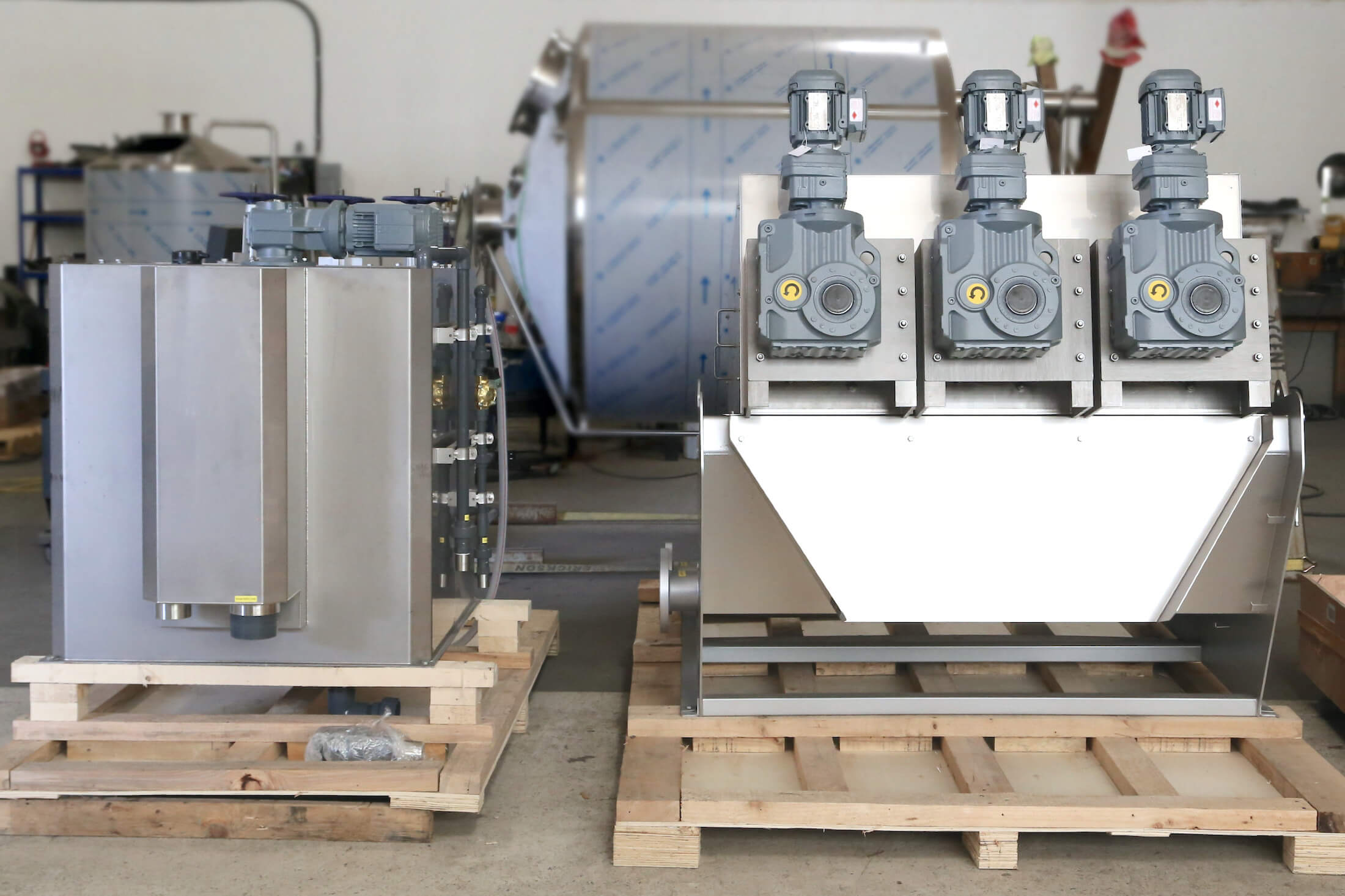

Trident’s 1xx and 2xx MD presses offer compact design and remarkable performance.

Effective sludge treatment and the ability to manage disposal costs is an important aspect at many wastewater operations. But it can be a challenge for smaller, remote or mobile applications with lower flow rates. Trident’s 1xx and 2xx MD presses are the ideal solution for these projects. With their compact design and footprint they deliver remarkable performance.

Depending on the sludge type, a single cylinder MD131 can process up to 2 m3/hr (~ 9 gpm). The dual cylinder MD132 not only doubles the capacity, it also addresses redundancy requirements. The next model up is the MD202 which can process up to 8 m3/hr (~35 gpm). The MD presses are available as skid mounted systems and include a flocculation tank. If required they will be supplied as a package with sludge feed pump, polymer system, cake conveyor and controls.

Bottom left image: Samples of the feed, filtrate and cake. Bottom right image: Effluent water from the dewatering cylinder is collected in the filtrate tank below.

The MD131 footprint including motors and floc tank is approx. 73.5” L x 17” W (approx. 186 cm x 43 cm) with a dry weight of 452 lbs (205 kg). The dual cylinder MD 202 measures 104.5” L x 35” (approx. 265 cm x 88 cm) with a dry weight of 1,037 lbs (470 kg).

An important consideration, especially for smaller plants, is how operator and maintenance friendly the equipment is. This is another area where Trident’s equipment shines. Due to the self cleaning effect of the rotating discs there is little to no operator attendance required for wash-downs. In fact, all MD presses are equipped with a CIP spray bar. The automation system controls the spray intervals depending on the client’s requirements. Low speed operation combined with low HP motors help extend the equipment life. A very important benefit from a maintenance perspective are the cartridge style dewatering cylinders, which can be replaced onsite usually within a few hours, eliminating excessive downtime or the need for temporary backup.

To learn more about Trident’s MD sludge presses, give our team a call at 1.800.799.3740.