Controls and Automation

Customized Automation Solutions for Resource Recovery Applications

The Trident Automation System is a customized controls solution designed to manage the process variables of advanced liquid waste management. Based on specific input parameters provided by sensors and customized event action circuits, the controls ensure optimal performance of the system, even under changing conditions.

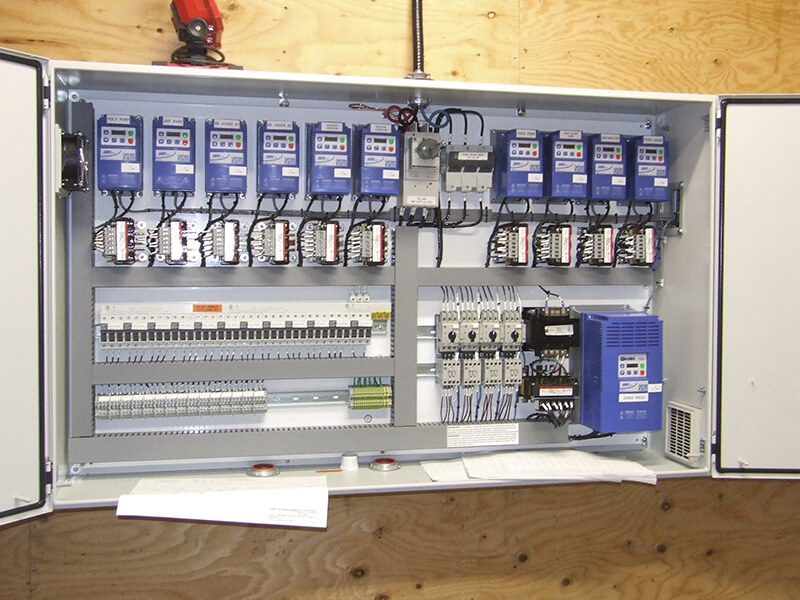

Image: The VFDs control the system based on specific input parameters provided by a number of different sensors and customized event patterns. This ensures optimal performance of the system around the clock.

The automation system includes Programmable Logic Controller (PLC) and Variable Frequency Drive (VFD) motor controls as required, as well as sensors and signaling devices, air valve actuators, HMI operator touch-panels, UL listed enclosed industrial control panel, and a secure internet router.

Standard features include: individual component monitoring, embedded input data configuration, Ethernet IP communication, text notification, remote access function, total run-time monitoring and I/O. The automation system is specifically developed for each installation. Its configuration commonly requires a P&ID which is developed during the project design & engineering stage.

Trident automation packages are available for the Nutrient Recovery and Bedding Recovery System, as well as standalone equipment.