Trident Wave Separator

The efficient choice for sludge thickening

The Trident Wave Separator is a sludge thickening machine with an efficiency that is second to none. The Wave Separator’s innovative working principle ensures effective separation in many sludge thickening applications while requiring a very low Opex. Slow moving oval discs gently move the material across the separation table, achieving high capacities and excellent capture rates. The Wave Separator can be operated fully automated 24/7 or process sludge in batches. The Wave Separator technology is scalable to suite multiple applications and varying volumes of material.

Image: Reliable high capacity thickener with compact foot print and low operating costs. Available with flocculation and mixing tank.

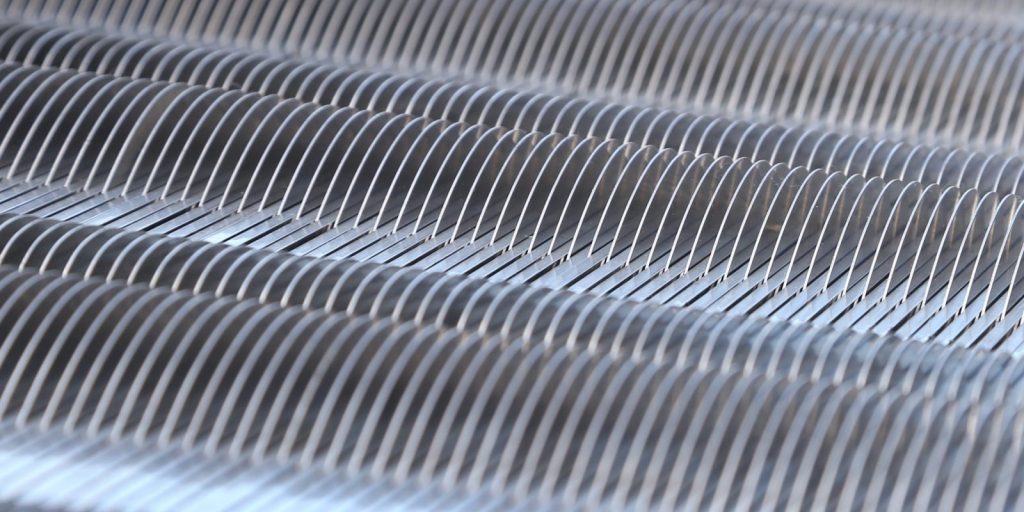

Image: Slow moving oval discs, mounted on columns, convey the material across the separation screen allowing liquid to escape through the slit bar filter.

Applications

The Trident Wave Separator is successfully used in a wide range of applications that focus on sludge treatment of organic or inorganic materials. Some of the applications include:

- Food wastes in food processing

- Paint and coatings effluent

- Tanneries

- Metal processing industry

- Fishery wastes treatment

- Algae harvesting

- Primary filtration for wastes coming from grease traps

Features and benefits

Trident’s Wave Separator is a very affordable technology both from a capital cost and an operational perspective. The system can be operated fully automated 24/7 with minimal operator attendance. Its self-cleaning design eliminates the need for a spray bar or frequent backwash procedures. The equipment is powered by a low-horsepower motor ensuring low operational expenses. The Wave Separator also helps reduce the downstream treatment capacity of sludge dewatering equipment such as the MD Press.

- Low speed, low energy operation reduces operational costs

- Continuously rotating discs perform self-cleaning and eliminate the need for wash water

- Consistent throughput of material for reliable and continuous operation

- Variable speed drives allow easy adjustments of sludge concentration

- Very low maintenance requirements minimizes Opex and down time