When the Santa Fe, New Mexico wastewater treatment plant started to plan an upgrade to…

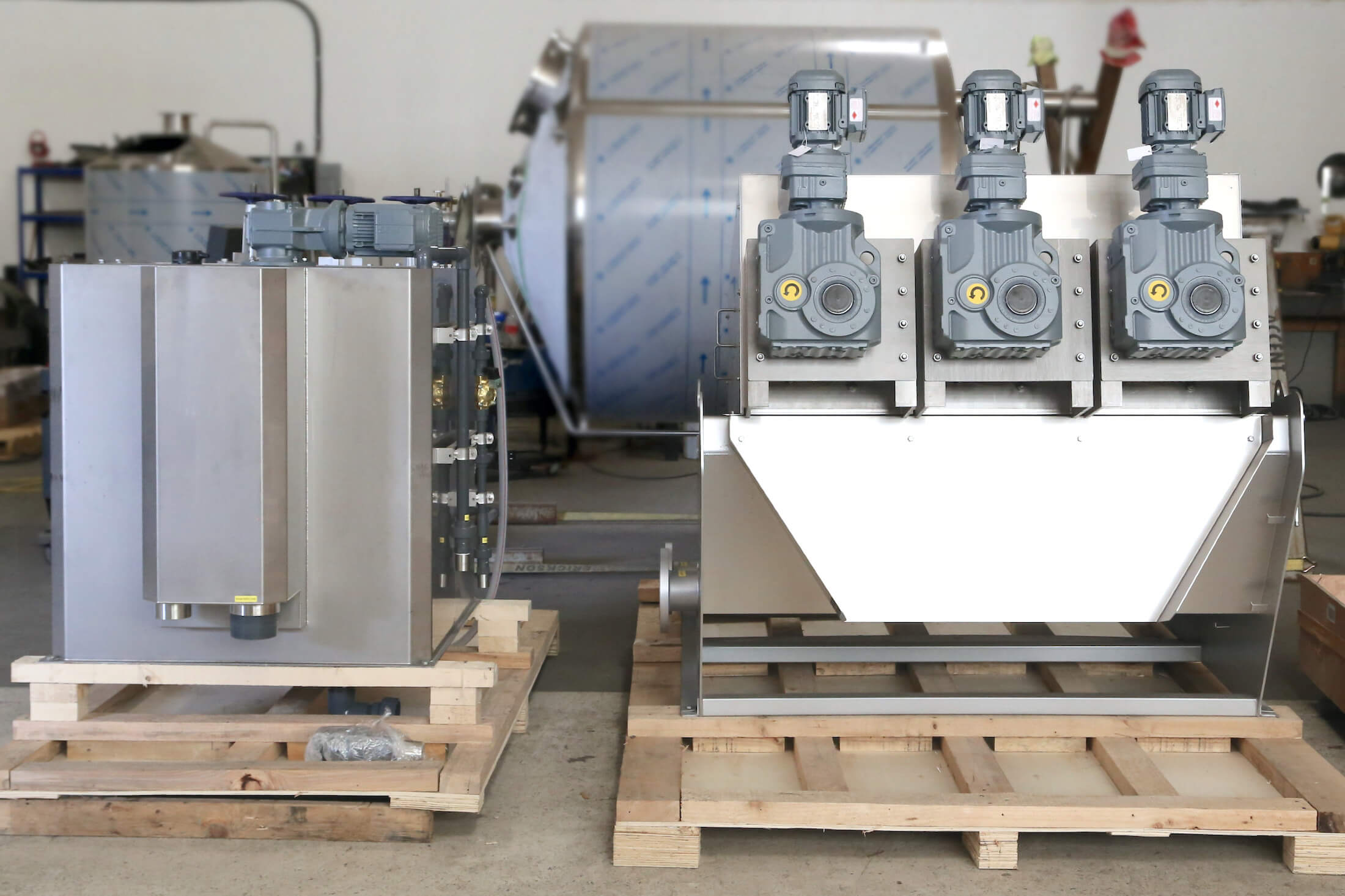

Sludge press with built-in redundancy

Trident’s MD 313 sludge press features three dewatering cylinders.

The sludge dewatering press Trident MD 313 is equipped with three dewatering cylinders. This model has a recommended sludge processing capacity of approx. 25 to 135 gpm. A detail that sometimes gets overlooked but can make a big difference for the operations team, is that the cylinders of the MD 2/3/4xx models can be individually controlled. The machine can run with two out three cylinders. The ‘built in’ redundancy allows the machine to maintain operation even in the rare case when the primary cylinders require maintenance or a rebuild (for most applications recommended every 3-5 yrs). Not having to worry about a temporary replacement or prolonged downtimes is a big advantage.

The MD Press is a great option in many wastewater applications, whether it’s a municipal WWTP or one the many industrial applications:

- chemical

- food processing

- manufacturing

- oil & gas

- organics & food waste

- pharmaceutical

- pulp & paper

- travel, remote & mobile applications

- water treatment

- …and many more.

The dimensions of a MD313 including motors and floc tank are approx. 151” L x 64” W x 66″ H (approx. 383 cm x 162 cm x 167 cm) with total power 2.5 HP and a dry weight of 4,013 lbs (1,820 kg).

Excellent solids removal, very low Opex and competitive equipment cost are important ROI considerations and ultimately make it an easy decision to invest in a Trident MD Press. Talk to a Trident representative and learn how the MD Press can help for your project.

Left image: The MD 313 features three dewatering cylinders that can be controlled individually via the PLC system. Right image: The floc tank is equipped with three feed connection outlets with individual gate valves that allow the operator to turn off the feed to a single or all cylinders.