Sludge dewatering at Santa Fe WWTP

When the Santa Fe, New Mexico wastewater treatment plant started to plan an upgrade to their sludge dewatering process, Trident’s team consulted with the client and their engineering team to help assess suitable treatment options. The client emphasized the importance of separation performance as well as labour and energy efficiency, and it was quickly determined that the sludge dewatering equipment from Trident’s multi disc (MD) press lineup was the ideal solution. In very short order the technical team determined the equipment sizing and successfully completed sample testing. With a design flow rate of 45 gallons per minute at approx. 1.5% TS the team chose the three-cylinder MD 313 Press model.

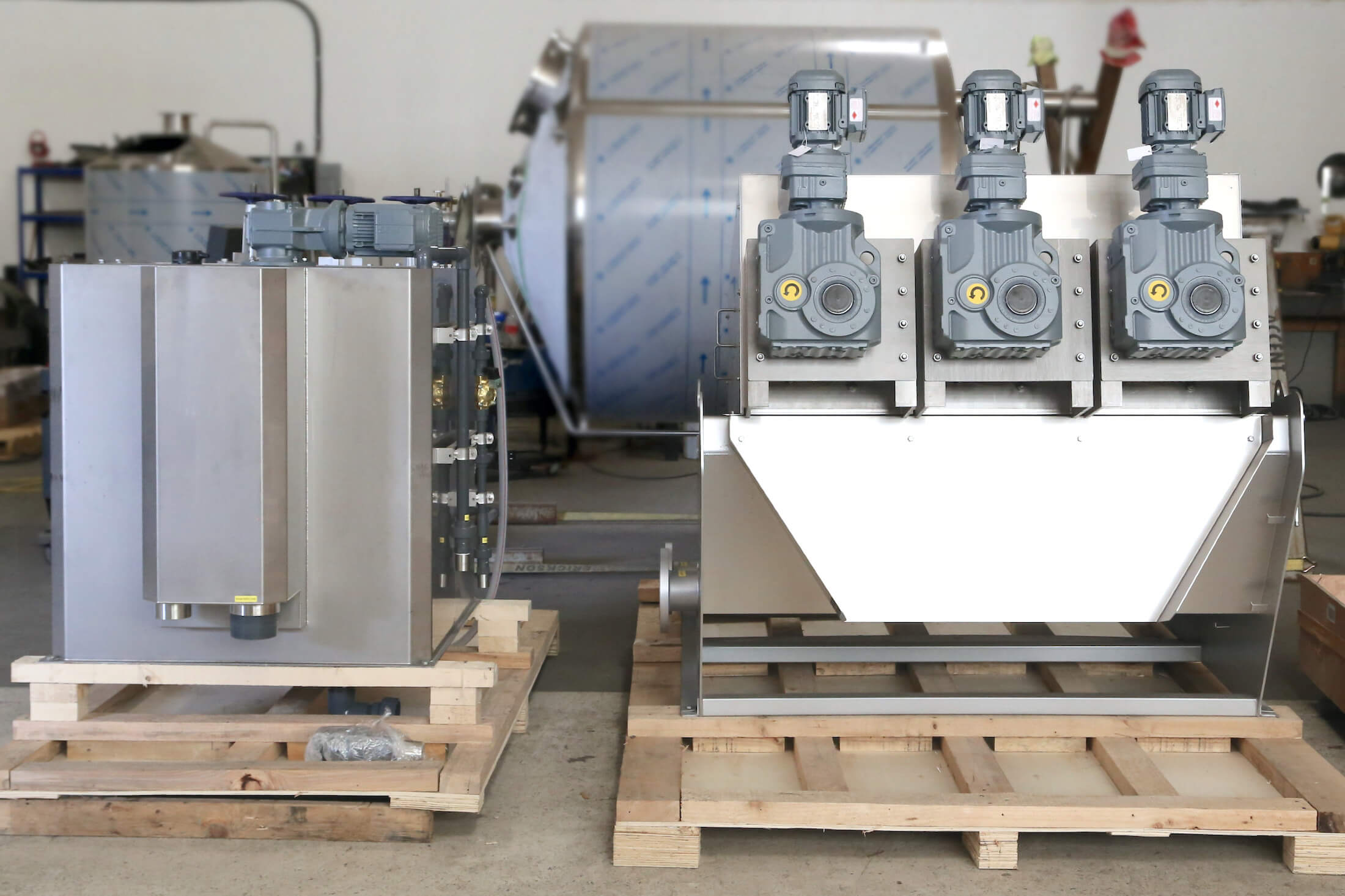

Image: The three-cylinder MD Press 313 with flocculation and mixing tank prior to shipment to the Santa Fe wastewater treatment plant.

Multi-cylinder models like the MD 312/313 or the larger MD 412/413/453/454 allow the operator the option to run individual cylinders and have extra capacity for peak flows if needed. They can rotate between several cylinders over a longer period. This substantially increases the equipment life at relatively low extra capital expenditure. The footprint of the MD 313 is approx. 150 inches by 65 inches. The total power for all four motors is 2.5 HP.

Image: The flex hoses connect the flocculation and mixing tank with the corresponding inlets on the press’ dewatering cylinders. The operator can manually control the flow to the individual cylinders with gates valves.

The MD Press 313 at the Santa Fe plant delivers excellent sludge dewatering results with cake solids at approx. 20% TS. The machine has proven to be a critical contributor in achieving the plant’s goal of reducing sludge volume. All while requiring minimal operator oversight. At this project Trident also supplied the integrated polymer makedown system, a shaftless screw conveyor and automation components.

For more details visit Trident on YouTube or call 1.800.799.3740.