Earlier this month our team had an opportunity to showcase advanced manure treatment with the…

Manure treatment system for flush dairies

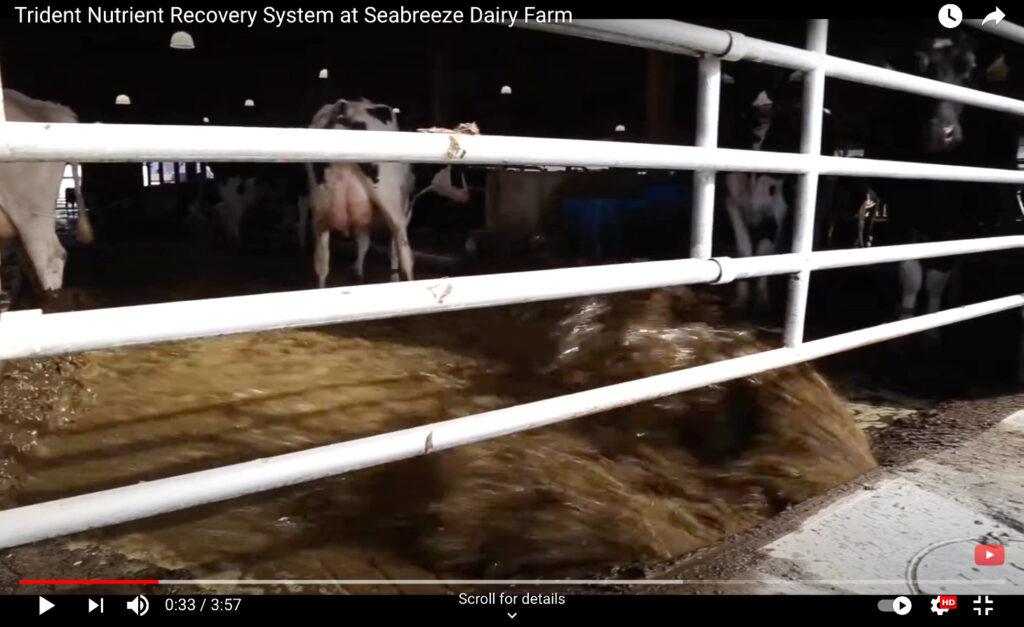

Manure treatment system for flush dairies – February 22nd, 2021. A manure treatment system that is designed for a flush dairy needs to address very specific requirements. A key criteria is the ability to handle large flows of very dilute manure. Because flush barns use water to collect the manure in the alleys, the solids content can be less than 2% TS.

Depending on the farm’s objectives this can be achieved with a basic manure separation or a more advanced multi-step treatment. High capacity drum screens coupled with screw or roller presses can capture a good amount of the fibrous manure particles. Farmers that are determined to go to the next level, invest in secondary treatment . The main reason for this is the ability to capture the remaining coarse and suspended fine solids. Now the farm benefits from several options for the effluent. The lagoon will be substantially cleaner and the recycled water is now clean enough to be used for e.g. high efficiency drip irrigation. The clean water also improves the performance sand lanes or alley flush.

ADVANCED MANURE TREATMENT SYSTEM

A multi-step manure treatment combines primary and secondary separation. If desired, the treatment can also be extended with an additional filtration step. Each treatment step is fine-tuned to target a specific component of the dilute manure stream. A network of flow meters, sensors, pumps and controls ensures smooth operation from feed to output and every step in between.

Video: This video shows an example of a fully integrated multi-step manure treatment on a 350 cow flush dairy. Learn how Trident can help transform your manure management and give our team a call at 1-800-799-3470.